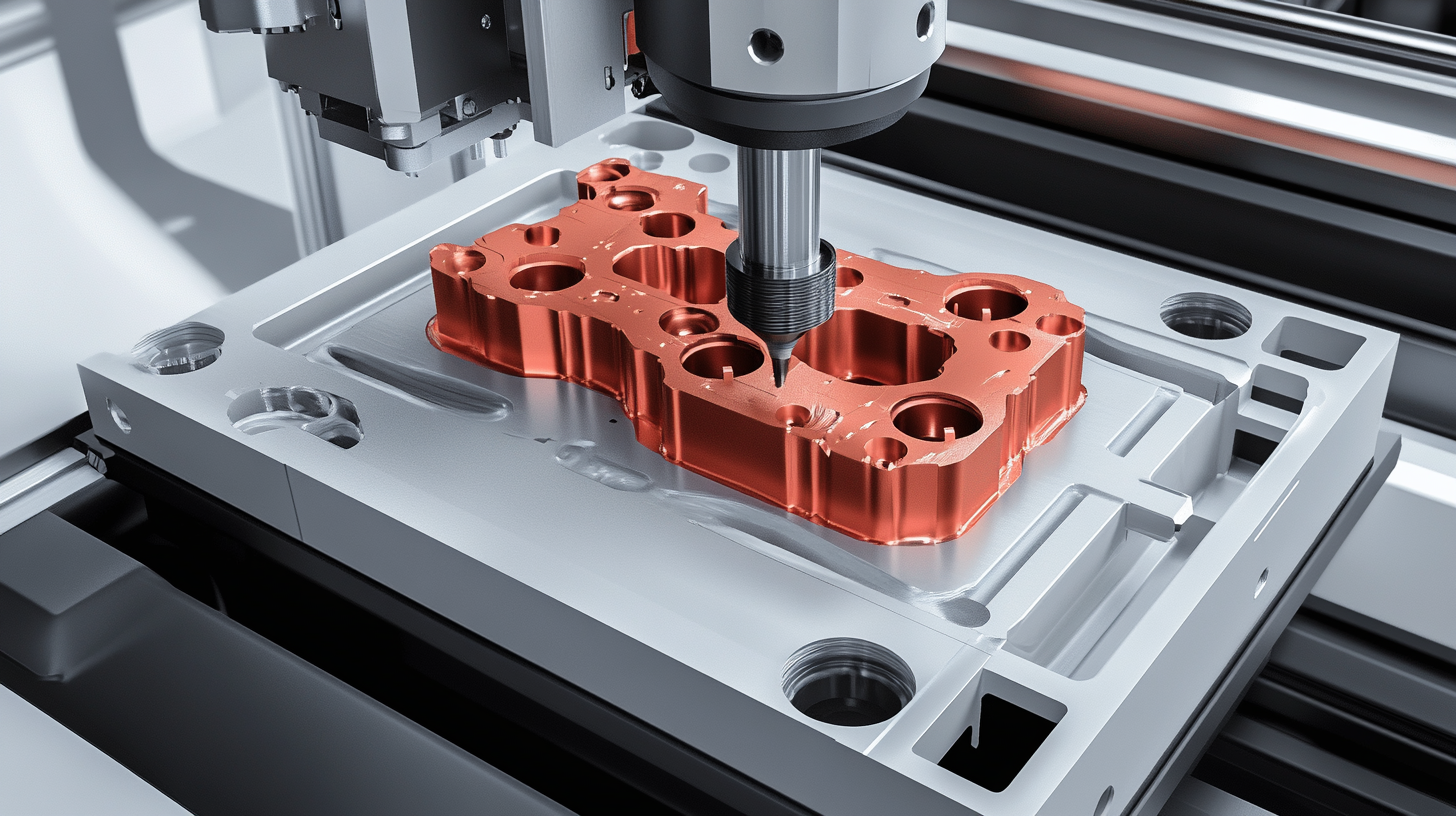

Multi-cavity molding is a highly efficient injection molding strategy that allows manufacturers to produce multiple identical parts in a single cycle. By using multiple cavities within the same mold, multi-cavity molding significantly increases production output, reduces per-part costs, and optimizes cycle times, making it an ideal choice for high-volume manufacturing.

Let’s explore the key ways multi-cavity molding improves production efficiency and helps manufacturers scale their operations effectively.

Why Does Multi-Cavity Molding Improve Output?

Multi-cavity molds allow multiple parts to be produced simultaneously, increasing overall output without extending cycle time. Unlike single-cavity molds, which produce one part per cycle, multi-cavity molds can produce multiple identical parts in a single shot, leading to significantly higher production rates.

For example, a four-cavity mold can produce four parts in the same time it takes a single-cavity mold to produce one. This increased efficiency is particularly beneficial for industries requiring mass production, such as automotive, consumer goods, and medical devices.

How Does Multi-Cavity Molding Reduce Per-Part Costs?

Producing multiple parts per cycle reduces material waste, labor costs, and machine time per part, leading to lower per-part costs. While the upfront cost of a multi-cavity mold is higher than a single-cavity mold, the overall cost per part decreases as production volume increases.

Key cost-saving benefits include:

- Lower Machine Time Per Part: Since multiple parts are molded at once, machine operation costs are spread across more units.

- Reduced Labor Costs: Fewer cycles mean less handling and secondary processing time.

- Optimized Material Usage: Efficient runner systems in multi-cavity molds minimize material waste.

How Does Multi-Cavity Molding Improve Consistency and Quality?

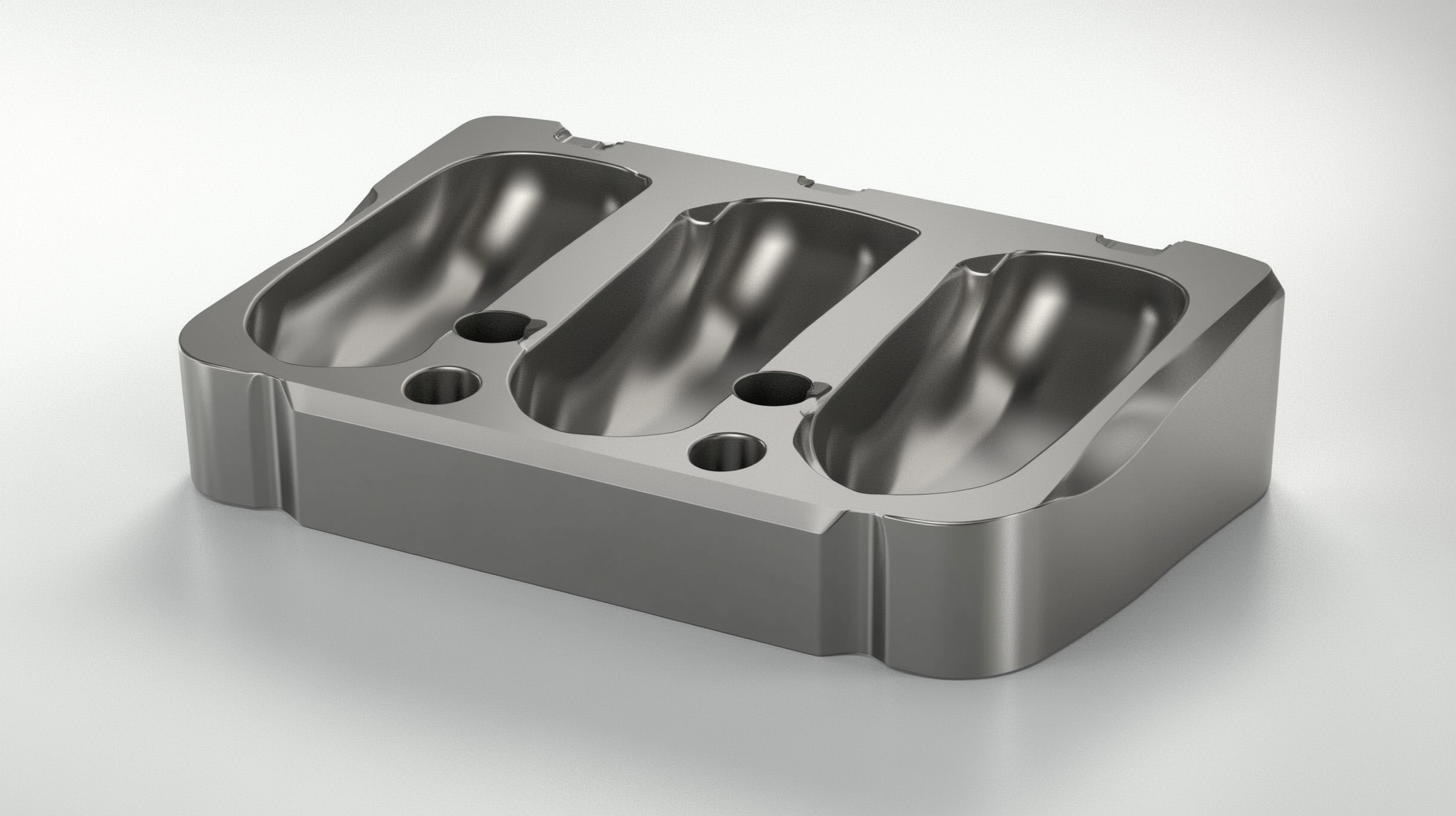

Multi-cavity molds ensure uniform part production, reducing variations that can occur when using multiple single-cavity molds. Since all cavities are filled simultaneously under the same conditions, part consistency is greatly improved.

Factors that contribute to quality improvements:

- Uniform Pressure and Cooling: Each cavity experiences the same injection pressure and cooling rate, preventing warping and inconsistencies.

- Better Process Control: Consistent production parameters across all cavities lead to improved dimensional accuracy and reduced rejection rates.

Comparison of Single-Cavity vs. Multi-Cavity Molds

| Feature | Single-Cavity Mold | Multi-Cavity Mold |

| Production Speed | Slower, produces one part per cycle | Faster, multiple parts per cycle |

| Initial Cost | Lower mold cost | Higher mold investment |

| Per-Part Cost | Higher per unit | Lower per unit |

| Machine Efficiency | Requires more machine cycles | Fewer cycles, higher efficiency |

| Best For | Low-volume production, prototyping | High-volume, mass production |

Key Tips for Maximizing Efficiency with Multi-Cavity Molds

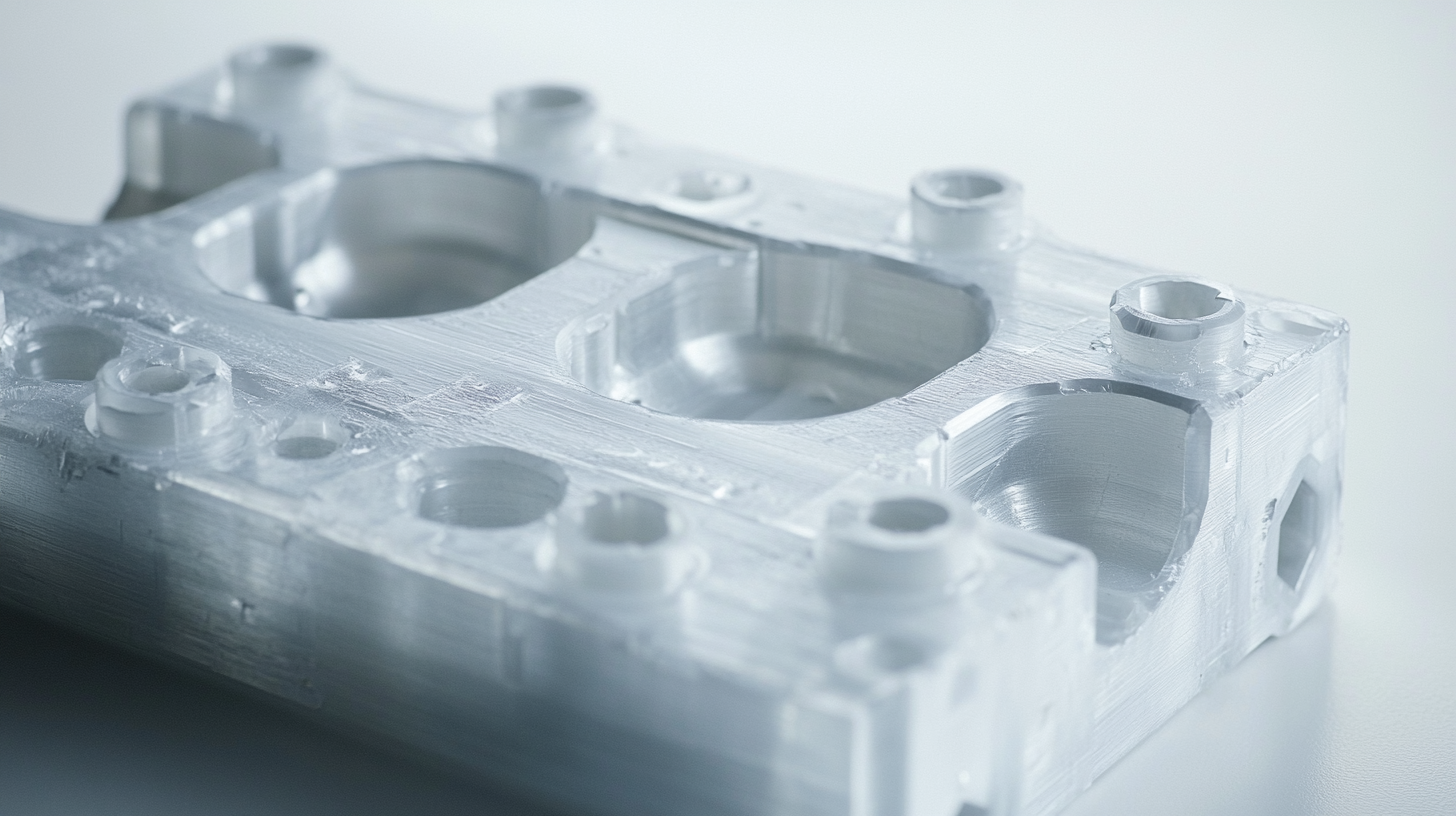

Optimize Runner and Gate Design: Ensure balanced material flow to all cavities for consistent part quality.

Fine-Tune Process Parameters: Adjust injection speed, cooling, and pressure to accommodate multi-cavity molding requirements.

Use High-Quality Mold Materials: Durable molds extend lifespan and reduce maintenance costs.

Monitor for Variations: Regular quality checks ensure uniformity across all cavities.

Conclusion

Multi-cavity molding is one of the most effective ways to enhance production efficiency, reduce costs, and improve part consistency in injection molding. By producing multiple parts per cycle, manufacturers can significantly increase output, lower per-part costs, and optimize machine utilization.

For expert assistance in implementing multi-cavity molding for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Feb-20-2025